Hi!

"What if..."

How many game changing products that we take for granted started their lives with those two small words?

We've had a few "what if' conversations over the years, today I want to tell you about one of them.

What if we didn't need to wear a jacket to be protected on the bike?

What if our layering didn't always need to end in a protective layer?

What if we could develop a baselayer that also protected us?

What if we could invent a fabric that was thinner, lighter and more difficult to tear than our adventure riding community have ever experienced?

There were a lot of "what if's" at the start of The Supershirt project, but the most important one, the one that the whole project hinged on, was the fabric.

Our product dev team spent a long time crunching the problem of the fabric, talking to textile designers, researching new and old textiles and looking at obvious and left field technologies.

The answer came in the form of a highly technical material more commonly found in heavy industry.

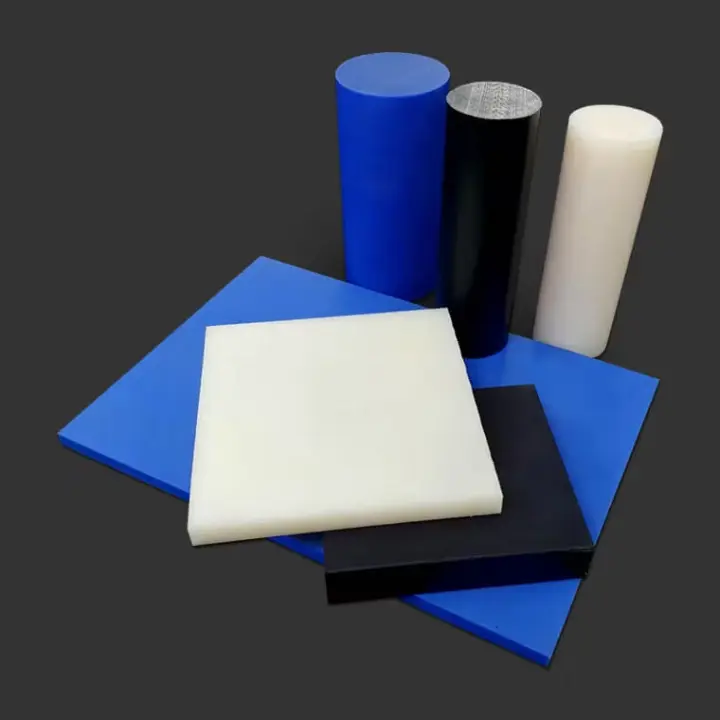

Ultra High Density Polyethylene (UHDPE).

Image https://dzhuarun.en.made-in-china.com/

It's used to make all manner of machine parts that need to withstand heavy wear and abrasion. UHDPE essentially starts its life as a big block of hard plastic, but the one use that I think is easiest to understand in the context of The Supershirt is marine rope. Tough, flexible, won't absorb water, and will withstand huge amounts of abrasion and wear and tear.

Image Amazon.com

It sounded perfect, if it weren't for the fact that it was a big chunky rope. How could we turn it into something you can wear?

The answer did not come entirely from us.

We are fortunate that our product dev team includes Steve, our textile partner with many decades of experience. He activated his network of mills and manufacturers and found a weaving expert that was up for the challenge.

They began the trial and error process of extracting strands of UHDPE and weaving it into a blend of nylon 6.6, elastane and silver ion yarns to create a fabric that could be worn next to the skin and no longer resembled marine rope.

Our mill uses textile machines similar to this one - image Solid State Clothing

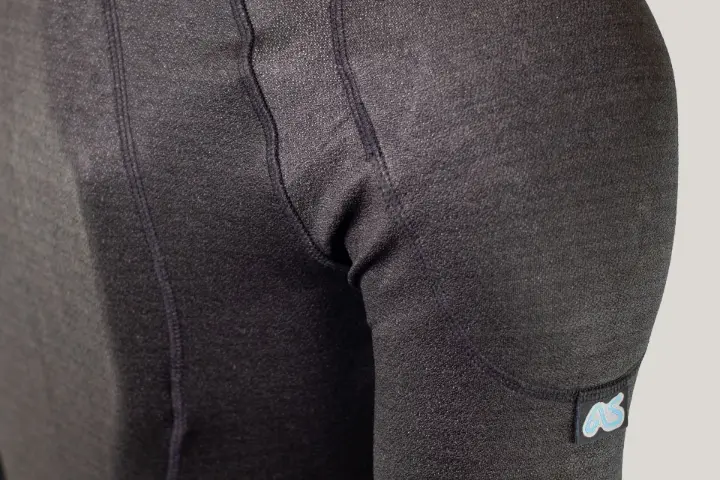

Almost as thin as a regular baselayer, this innovative new fabric was the key to passing abrasion tests and achieving CE AA certification.

(Interesting fact, we were a cat's whisker away from getting CE AAA, all body zones but one passed at AAA).

Take a look at this short film showing what happened when I tried to cut my Supershirt with a sharp knife (it's pretty impressive).

When The Supershirt launched a few years ago, our community of lightweight adventure riders immediately understood what it meant and how it would transform the way they geared up for their ride.

"I have been using armoured shirts for the last couple of years but I’ve always felt uncomfortable not having an anti abrasion layer during rallies or off road event unless of putting over the armoured shirt a jacket. The Supershirt has totally solved this problem, now it is my main armoured layer for almost any trip I do on or off road."

Word has spread and more riders have joined The Supershirt community, enjoying the freedom to ride with as few or as many layers as they like without compromising CE AA protection.

A few have even had the misfortune to put theirs to the test - read what Matt had to say about his crash here.

You are one email away from the launch of The Supershirt 2.0.

Here's what's changed.

- We now manufacture our Supershirt fabric at a specialised mill here in the UK.

- The Supershirt 2.0 ships with our new lighter, more flexible and breathable Flow elbow and shoulder armour.

- New Flow back and chest armour are optional extras.

All of this has allowed us to price the new Supershirt 2.0 more competitively than ever.

It's a wonderful feeling turning a "what if...' into "what next?"

I can't wait to launch with you.

See you in the next email.

😎

Greg Villalobos.

This story was first published in our email Newsletter. Subscribe now for the most ADV email you will get all week!